Safety in DNA

16 July, 2014 | The Machinist

ShareThe Machinist

July 2014

The Aditya Birla Chemicals Business has adopted safety as a key performance parameter to drive its business sustainably with operational excellence.

Today, every manufacturing business needs to incorporate safe work practices in its operations. It is all the more critical if the business is into handling of chemicals, some of which are hazardous and toxic in nature. That's why the Aditya Birla Chemicals Business has adopted safety as a key performance parameter to drive its business sustainably with operational excellence. In fact, it has incorporated safety in its organisational DNA across all the 14 manufacturing locations globally.

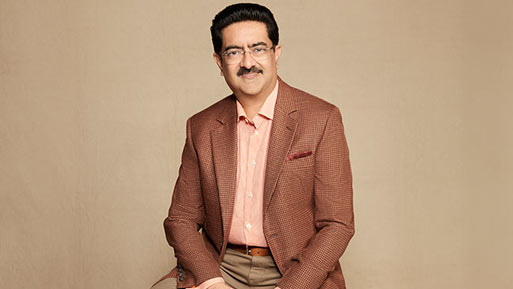

— Lalit Naik, Business Head, Aditya Birla Chemicals

To adopt the global best practices and to meet norms specific to chemicals hazard, the Aditya Birla Chemicals Business collaborated with DuPont Sustainable Solutions (DSS) - the knowledge consulting arm of DuPont. It initiated the journey about three years ago with Work Place Safety (WPS), wherein the at-risk behaviours are addressed to improve work practices to establish better operational discipline. The Business also extended its engagement to include Process Safety Management (PSM). With PSM, the manufacturing processes are routed through a 13-element wheel to address their risks both qualitatively and quantitatively as well as through driving control mechanisms to mitigate safety issues.

The WPS engagement at units identified focus areas. This included framing of the ten high risk standards and rolling them out for gap identification and support for strengthening the infrastructures to meet the standard requirements. The ten high risk standards encompass personal protection, work@height, materials handling, job safety analysis, permit to work, lock out tag out, hot work, scaffoldings, incident investigation and excavation. The Business also developed standard capability to train employees as well as all other stakeholders.

To drive WPS, Aditya Birla Chemicals Business formed six different sub-committees to cover Safety Rules &Procedures, Safety Observation &Audit, Incident Investigation, Capability Development &Communication, Safety in Transport &Distribution, and Contractor Safety Management with each unit led by a senior management team.

- Improvements in safety observation by all sections and reporting to tab the non-compliances.

- Reduction in the number of first aid cases at Indian Rayon plant at Veraval, Gujarat.

- Conducting process hazard analysis for key processes to adopt engineering controls so that any eventuality due to technical flaws gets minimised.

- Improvements in material handlings, energy isolation system.

- 100% enforcement of permit to work system across all areas.

- Reporting and investigation of incidents to correct the system.

Similarly for PSM, the Business c;reated one sub-committee per unit which works closely for developing process safety practices like technology, process hazard analysis, pre-start up safety review, emergency response and management of change. Each unit has an Apex Committee with its Unit Head as the Chairman to run the initiatives. The effectiveness of the engagement is first monitored through the Safety Observation (SO) Process and finally by trained first party and second party auditors during the auditing processes. The Business leadership (led by the Business Head) provides guidance and support through the Steering Committee.

Earlier safety was considered as the safety department's sole responsibility. Now it is part of the DNA of each and every individual in the Business, be it on the shop floor (technical or non-technical), in the administration department or at the corporate office. Importantly, employees are driven by safety whether they are working or at off work.

"With a journey of about three years with DuPont Sustainable Solutions, we have reached a stage where safety is imbibed in the DNA of the entire team. We have put the process in place to ensure continuity of use of safe work practices in a sustainable manner," says Lalit Naik, Business Head, Aditya Birla Chemicals. He believes that it's a journey and it should continue with the aim of making every workplace in the Business, a zero-incidents workplace.