Made in India

16 September, 2012 | Business India

ShareDaksesh Parikh

Business India

September 16, 2012

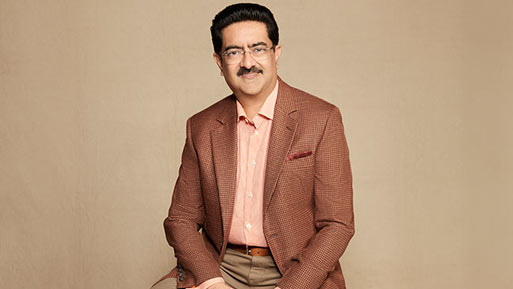

“Manufacturing must become the next big wave,” says Mr. Kumar Mangalam Birla, Chairman, Aditya Birla Group

India emerged as one of the fastest growing economies in the world over the past two decades. Yet the performance of one vital cylinder of India's growth engine, the manufacturing sector, has consistently lagged, compared to the service sector. As a result, the share of manufacturing in India's GDP has stagnated at around 16 per cent, while the services sector has catapulted to 63 per cent.

India emerged as one of the fastest growing economies in the world over the past two decades. Yet the performance of one vital cylinder of India's growth engine, the manufacturing sector, has consistently lagged, compared to the service sector. As a result, the share of manufacturing in India's GDP has stagnated at around 16 per cent, while the services sector has catapulted to 63 per cent.

.

This is in sharp contrast to countries such as China, Malaysia or Thailand, where the share of manufacturing in GDP ranges from 25 per cent to 35 per cent of GDP. Even in many developed economies (such as Japan, Germany, and even smaller countries such as Switzerland and Singapore), which have for long been witnessing an exodus of manufacturing, the sector still accounts for 20 per cent or more of GDP.

Most countries, regard manufacturing as the essential underpinning for an economy, notwithstanding the negative perception conveyed by terms such as 'smokestack' industries. A dynamic manufacturing sector is essential for sustaining growth, creating jobs, increasing value addition, ascending the technology curve, and ensuring national security. Each manufacturing job c;reates four to five additional jobs in the service sector.

In India, though, the gap between the manufacturing and service sectors continues to widen. Today, only 9 per cent of India's workforce is employed in manufacturing. Over the next decade and half, the number of entrants into the labour force is projected to swell by 250 million.

With farm jobs likely to contract, and services growth moderating, it is industry and manufacturing that will have to take the lead in creating jobs. Hence, it is appropriate that the government and Planning Commission have set a target to increase the share of manufacturing to 25 per cent of GDP by 2022. This implies that the sector must grow at 12-14 per cent per year.

This is a realistic target. The shift of global manufacturing to Low Cost Countries (LCCs) is expected to gather steam. According to a CII-McKinsey report, offshoring to LGCs will triple over the next five years, to over $4,000 billion. Furthermore, a larger percentage of the offshored activity will require higher skills. This opportunitycan be harnessed by India.

To do so, we need a coherent and focused policy, buttressed by infrastructure development. The weakness in implementation of our policies relate to the slow approvals process, the multiplicity of ministries involved, (often acting at cross-purposes), difficulties in land acquisition, and an indirect tax structure marked by multiple and high taxes. As regards to infrastructure, for any major Indian project, entrepreneurs have to virtually set up their own infrastructure, from captive power plants, railway sidings and access roads, down to medical and school facilities.

India has the potential to capitalise on this global shift and become a global manufacturing hub, just the way it has become an IT hub. It is not a far-fetched vision. The ingredients are there - talent, entrepreneurship, raw material and a large internal market, all of which render economies of scale. That India's manufacturing capabilities can be benchmarked against global players across several sectors is indisputable. Manufacturing must become the next big wave.